Welding station

We offer extensive welding capabilities in the form of industrial robotic welding stations – one station with a collaborative robot and two laser welding stations using TRUMPF and PRIMA POWER LASERDYNE machines. These welding capabilities are suitable for medium and large series production. For small or prototype series, we use manual welding stations with fixture tables.

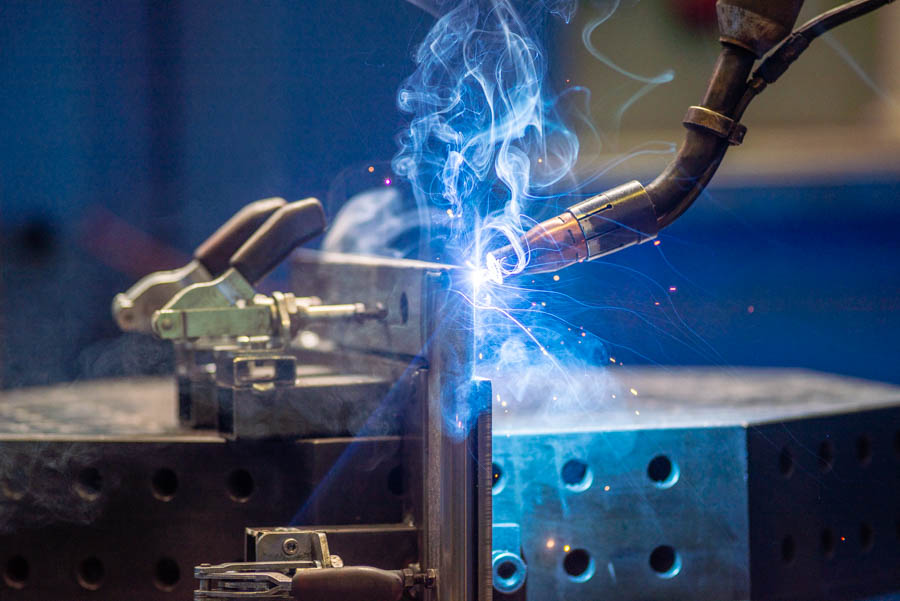

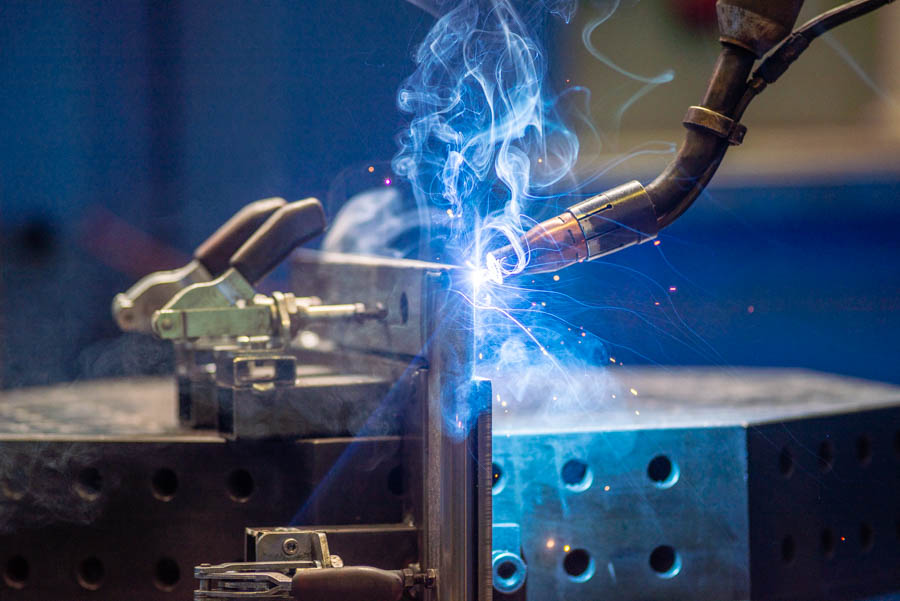

MANUAL WELDING

TECHNICAL PARAMETERS

- 15 welding stations

- Welding methods: MIG-MAG, PLASMA TIG, LASER

ROBOTIC WELDING

TECHNICAL PARAMETERS

- 3 robotic welding stations

- MIG/MAG welding current 480 A

- PLASMA TIG welding current 480 A

- MicroMIG welding current 300 A

- We weld: structural steel, stainless steel, aluminium

- Maximum weldment size: 2,500x1,600x1,000 mm of length

- Maximum weldment weight 250 kg

COLLABORATIVE ROBOT MIG/MAG

TECHNICAL PARAMETERS

- MIG/MAG welding current 400 A

- We weld: structural steel, stainless steel, aluminium

- Suitable for frequently recurring and smaller series

- Shorter preparation times compared to industrial robots

- Maximum reach: 1,500 mm

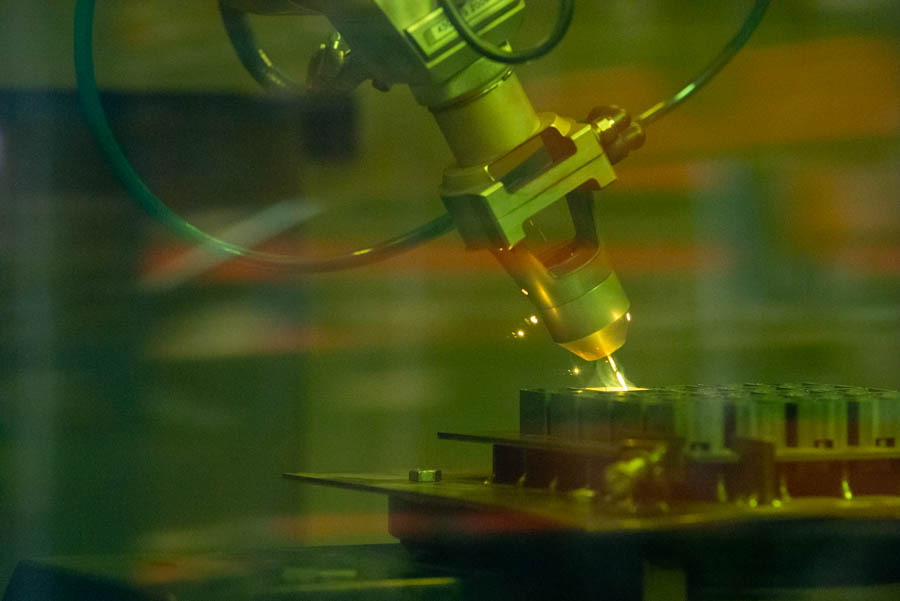

LASER WELDING

TECHNICAL PARAMETERS

- The laser source power output is 4 kW

- We weld: structural steel, stainless steel, aluminium

- Maximum weldment size: 4,000x1,500x750 mm of length

- High weld homogeneity

- High weld speed and stability

- Minimal heat-affected zone around the weld

- Low product deformation

- Possibility of welding in hard-to-reach places